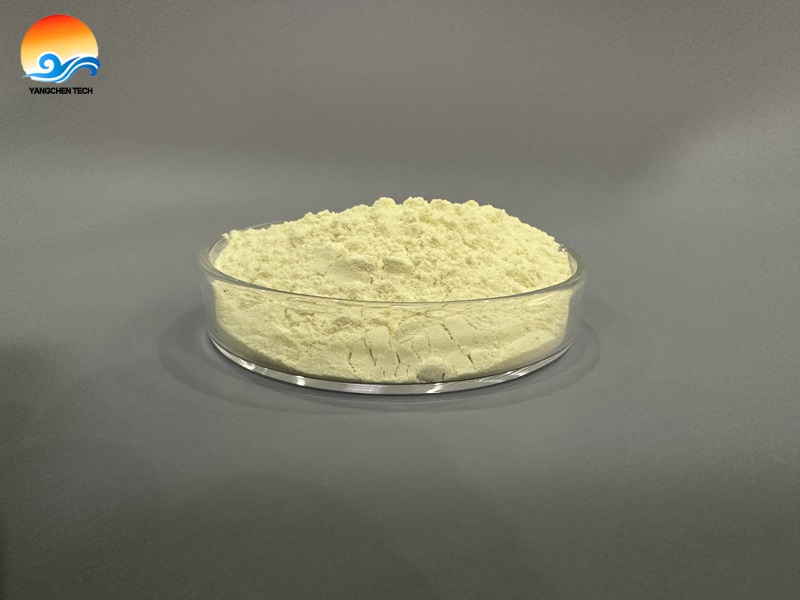

Bismaleimide resin powder manufactured by Yangchen Tech are versatile and high-performance materials used in various adhesive applications due to their exceptional properties such as thermal stability, mechanical strength, and chemical resistance.

Certification of Analysis by Yangchen Tech

|

ITEM |

Limits |

Results |

|

Appearance |

Yellow powder |

Yellow powder |

|

Solubility |

Dissolved, with trace impurities |

Fully soluble, clear |

|

Melting Point℃ |

150-160 |

155-158 |

|

Ash% |

≤0.3 |

0.06 |

|

Water% |

≤0.5 |

0.12 |

|

Acidity mgkoH/g |

≤5 |

1.0 |

|

Gel time |

≤300 |

160 |

Applications of Bismaleimide Resin in Adhesives

1. Aerospace Industry:

Structural Bonding: Used for bonding critical structural components in aircraft and spacecraft. Their high thermal resistance and mechanical strength make them ideal for applications where durability and reliability are paramount.

Composite Materials: Essential in bonding composite materials used in aircraft parts, ensuring strong, durable, and lightweight structures.

2. Automotive Industry:

HighPerformance Components: Employed in bonding highperformance components such as engine parts, heat shields, and exhaust systems. The adhesives need to withstand high temperatures and mechanical stresses.

Lightweight Structures: Used to bond composite materials and lightweight structures in vehicles, contributing to overall weight reduction and improved fuel efficiency.

3. Electronics Industry:

Microelectronics Assembly: Used in the assembly of microelectronic devices where thermal stability and low dielectric constants are critical.

Printed Circuit Boards (PCBs): Applied in bonding layers within PCBs, ensuring the stability and reliability of electronic circuits under thermal and electrical stress.

4. Defense Industry:

Weapon Systems and Military Equipment: Utilized in assembling weapon systems and military equipment that must endure harsh environmental conditions and high mechanical stresses.

Armored Vehicles: Applied in bonding materials for armored vehicles, providing enhanced durability and impact resistance.

5. Industrial Applications:

High Temperature Machinery: Suitable for bonding components in industrial machinery and equipment that operate at high temperatures and require robust adhesive performance.

Chemical Processing Plants: Used in bonding components exposed to aggressive chemicals and high temperatures, ensuring longlasting and reliable bonds.

6. Marine Industry:

Boat Manufacturing: Used in constructing and repairing boats, offering excellent resistance to water, salt, and harsh marine conditions.

Offshore Structures: Applied in bonding components of offshore platforms and other marine infrastructure, ensuring robust and durable performance in demanding environments.

7. Sports and Leisure:

High Performance Sports Equipment: Employed in manufacturing highperformance sports equipment such as racing bicycles, skis, and other gear, where lightweight and strong bonding are essential.

Recreational Vehicles: Used in bonding components of recreational vehicles, ensuring durability and resistance to various environmental conditions.

Advantages of BMI Resins in Adhesives

High Thermal Stability: Can withstand high temperatures without degradation.

Excellent Mechanical Strength: Provides strong and durable bonds.

Chemical Resistance: Resistant to a wide range of chemicals and solvents.

Low Dielectric Constant: Suitable for electronic applications where electrical insulation is important.

LongTerm Durability: Maintains performance over extended periods, even in harsh conditions.

Bismaleimide resins are crucial for producing highperformance, reliable, and durable adhesives used in various advanced industrial applications.Welcome Inquire!

1. Wheels: Powder coating is often used to enhance the appearance of wheels and provide protection against chips, scratches, and corrosion.

1. Wheels: Powder coating is often used to enhance the appearance of wheels and provide protection against chips, scratches, and corrosion.