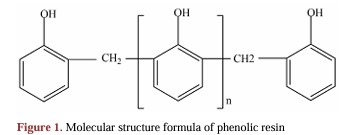

Modified phenolic resin overcome the shortcomings of phenolic resin, such as poor heat resistance and low mechanical strength. They offer excellent mechanical properties, strong heat resistance, strong bonding, and chemical stability. They are widely used in compression molding powders, coatings, glues, fibers, anti-corrosion, and thermal insulation applications.

1. Applications of Modified Phenolic Resins in Compression Molding Powders

Compression molding powders are essential for the production of molded products. They are primarily made from modified phenolic resins. In manufacturing, a common method involves using both roller compaction and twin-screw extrusion. Wood is used as a filler to impregnate the resin, and other reagents are then added and mixed thoroughly. The powder is then pulverized to produce compression molding powder. Materials such as quartz can be added to produce compression molding powders with enhanced insulation and heat resistance. Compression molding powders are a raw material for various plastic products, which can be manufactured industrially through injection molding or compression molding. Figure 2 shows the application of modified phenolic resin in compression molding powders. Compression molding powders are primarily used in electrical components such as switches and plugs for household items.

2. Application of Modified Phenolic Resins in Coatings

For 70 years, coatings have used phenolic resins. Rosin-modified phenolic resins or 4-tert-Butylphenol formaldehyde resin are the main ones in phenolic coatings. These resins make coatings better at resisting acid and heat, so they're common in lots of engineering projects. Still, because they give things a yellow color, you can't use them if you want a light-colored finish. Besides being mixed with tung oil, they can also be blended with other resins. To increase a coating's alkali resistance and air-dried hardness, alkyd resins can be added to improve the coating's alkali resistance and hardness. For coatings requiring acid and alkali resistance and good adhesion, epoxy resins can be added to enhance the coating's performance. Figure 3 illustrates the application of modified phenolic resins in coatings.

3. Application of Modified Phenolic Resins in Phenolic Adhesives

Phenolic adhesives are mainly made from modified thermosetting phenolic resins. If phenolic resin is used to create adhesives, its viscosity can be a problem, restricting it to plywood bonding. But, modifying phenolic resin with polymers can improve its heat resistance and adhesion. Phenolic-nitrile adhesives can even have good mechanical strength and toughness, especially when it comes to impact resistance.

4. Application of Modified Phenolic Resins in Fibers

Phenolic resins also have a wide range of applications in the fiber industry. Phenolic resin is melted and drawn into fibers, which are then treated in polyoxymethylene. After a period of time, the filaments solidify, resulting in a fiber with a solid structure. To further enhance the fiber's strength and modulus, the modified phenolic resin can be mixed with molten low-concentration polyamide and drawn into fibers, as shown in Figure 4. The spun fibers are typically yellow and possess high strength. They will not melt or burn even at temperatures of 8,000°C. It will also self-extinguish in these harsh environments, preventing fires from occurring at the source. At room temperature, polyamide-modified phenolic resin fibers are highly resistant to concentrated hydrochloric and hydrofluoric acids, but less resistant to strong acids and bases such as sulfuric acid and nitric acid. These products are primarily used in factory protective clothing and interior decoration, minimizing employee injuries and fatalities in the event of a fire. They are also commonly used as insulation and thermal insulation materials in engineering projects.

5. Application of Modified Phenolic Resins in Anti-Corrosion Materials

Phenolic resins are used to make anti-corrosion stuff, but the modified versions are more common. You'll often see these as phenolic resin mastics, phenolic-epoxy composite fiberglass, or phenolic-epoxy coatings. A good example is phenolic-epoxy coatings, which mix the acid resistance of phenolic resins with the alkali resistance and stickiness of epoxy resins. This mix makes them great for protecting pipelines and vehicles from corrosion.

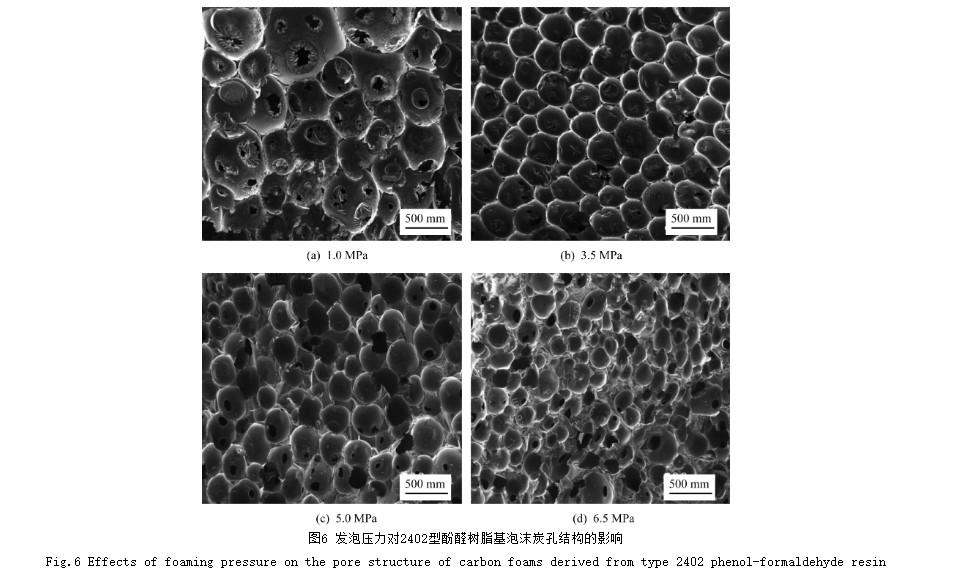

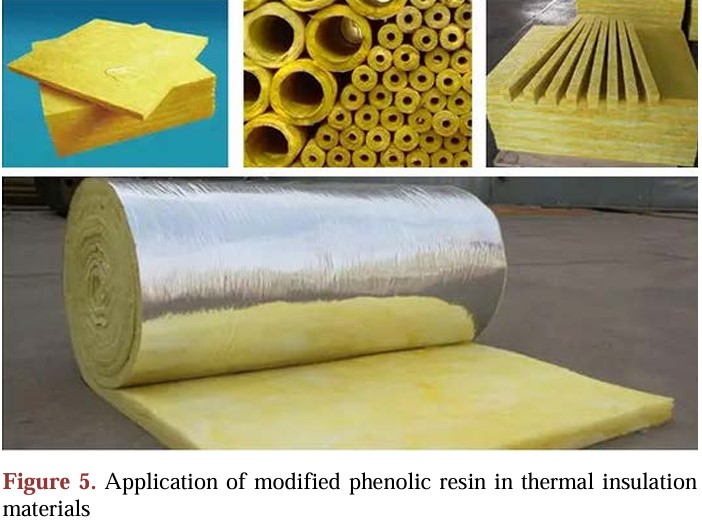

6. Application of Modified Phenolic Resin in Thermal Insulating Materials

Because modified phenolic resin offers superior heat resistance compared to pure phenolic resin, modified phenolic resin foams occupy a prominent position in the thermal insulation market, as shown in Figure 5. Modified phenolic resin foams also offer thermal insulation, are lightweight, and are difficult to spontaneously ignite. Furthermore, when exposed to flames, they do not drip, effectively preventing the spread of fire. Consequently, they are widely used in thermal insulation color-coated steel sheets, room insulation, central air conditioning, and pipes requiring low temperatures. Currently, polystyrene foam is the most widely used insulation material on the market, but its performance is far inferior to that of modified phenolic resin foam. Modified phenolic resin foam, due to its low thermal conductivity and excellent thermal insulation, has earned it the title of "King of Insulation" in the insulation industry.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com