Table of Contents

1. Introduction

Overview of the properties and application fields of cellulose acetate butyrate (CAB).

2. What is Cellulose Acetate Butyrate?

Introduce the chemical structure, preparation method and main properties of CAB.

3. Main Properties of Cellulose Acetate Butyrate

Detailed description of the physical properties, chemical stability and environmental friendliness of CAB.

4. Cellulose Acetate Butyrate Uses

Discuss the application of CAB in coatings, printing inks, nail care, varnishes and other fields.

5. What are the Different Types of Cellulose Acetate Butyrate? How Do I Choose?

Compare the models and properties of iSuoChem and Eastman CAB products.

6. Does My Project Really Need Cellulose Acetate Butyrate? What are Its Advantages?

Analyze the advantages of CAB resin and its applicable scenarios.

7. How to Choose the Right Cellulose Acetate Butyrate Product

Provide practical suggestions for selecting CAB products, including performance parameters and supplier selection.

8. FAQ

Answers to common questions about CAB, including safety, technical support and price advantages.

9. Conclusion

Summarizes the characteristics and application prospects of CAB, and emphasizes its importance as a modern industrial material.

1. Introduction

Cellulose Acetate Butyrate (CAB) is an important cellulose derivative that is widely used in many industrial fields due to its unique chemical structure and physical properties. CAB is usually a white powder with excellent solubility, flexibility and weather resistance, making it an ideal material for coatings, printing inks, nail care and varnishes. This article will explore the characteristics, application scenarios and how to choose the right Cellulose Acetate Butyrate product according to your needs.

2. What is CAB Cellulose Acetate Butyrate?

Cellulose Acetate Butyrate is a polymer material made from cellulose through acetylation and butyrylation reactions. Its molecular structure contains acetyl, butyryl and hydroxyl groups, and the content of these groups determines the performance of CAB. For example, an increase in the acetyl content increases the melting point and tensile strength of the material, while an increase in the butyryl content reduces the density and expands the solubility range.

Cellulose Acetate Butyrate has excellent moisture resistance, UV resistance, flexibility and transparency, and also has good electrical insulation properties. These properties make it perform well in coatings, inks and varnishes. 314.

3. Main properties of cellulose acetate butyrate

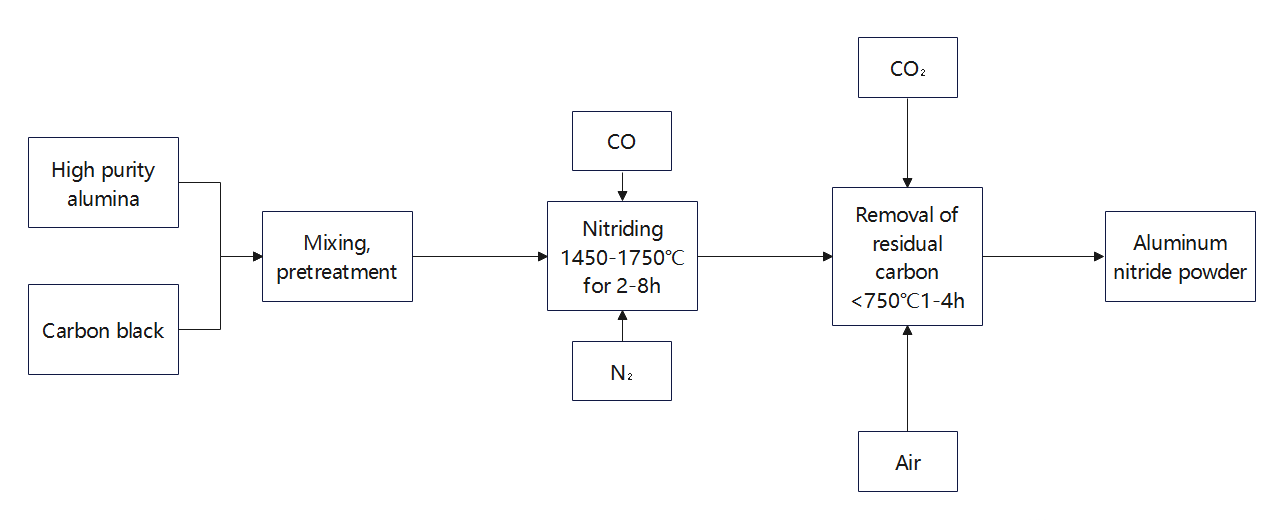

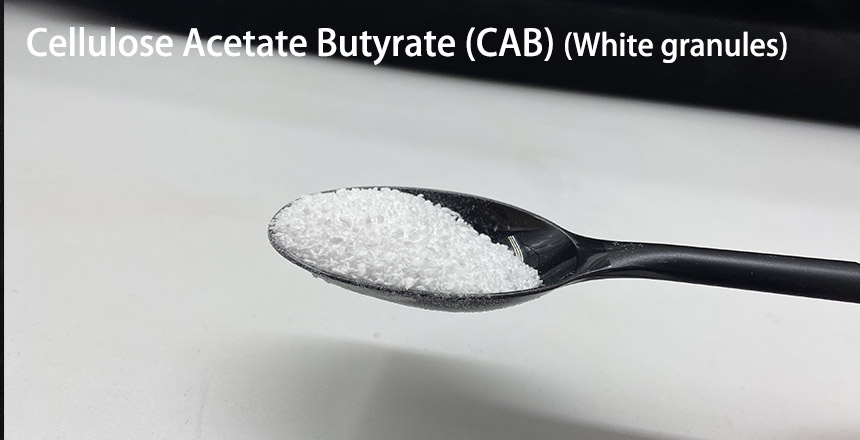

1. Physical properties: Cellulose Acetate Butyrate is usually a white powder with a density of 1.2-1.26 g/mL and a melting point range of 155°C to 240°C. Its refractive index is 1.475, with good transparency and optical properties.

2. Chemical stability: Cellulose Acetate Butyrate has good solubility in a variety of solvents and good compatibility with resins and high-boiling plasticizers. Its chemical corrosion resistance and weather resistance make it suitable for outdoor applications.

3. Eco-friendly: As a bio-based material, Cellulose Acetate Butyrate is degradable and has little impact on the environment, which meets the needs of sustainable development.

4. Cellulose acetate butyrate uses

1. Coatings: Cellulose Acetate Butyrate is widely used in automotive coatings, which can accelerate solvent evaporation, shorten drying time, and enhance the wear resistance and color stability of the coating. For example, Eastman CAB-381-0.5 can be used in automotive plastic coatings and wood coatings, which has the characteristics of improving leveling and increasing brightness. Currently, iSuoChem can provide completely equivalent models.

2. Printing inks: Cellulose Acetate Butyrate is added to inks as a leveling agent to improve leveling, eliminate paint film shrinkage, and enhance the adhesion and gloss of inks14.

3. Nail care: The application of Cellulose Acetate Butyrate in nail polish provides excellent flexibility and weather resistance, making nail polish more durable and beautiful3.

4. Varnish: Cellulose Acetate Butyrate can enhance adhesion, gloss and gloss retention when added to varnish, making the coating have extremely high gloss and wear resistance14.

5. Other application areas

5. What are the different types of Cellulose Acetate Butyrate CAB? How do I choose?

| Code |

Cellulose Acetate Butyrate Properties |

Equivalent Brand |

| iSuoChem CAB-381-0.1 |

Low solution viscosity, good solubility, suitable for wood, metal, plastic coatings, reducing shrinkage, shortening drying time, improving pigment control and inter-coating adhesion |

EASTMAN |

| iSuoChem CAB-381-0.5 |

Good solubility, higher viscosity, increased toughness, suitable for automotive basecoat, improves leveling and drying performance, improves orientation of flake metal pigments |

EASTMAN |

| iSuoChem CAB-381-2 |

Good solubility, higher viscosity, suitable for high viscosity coatings, enhanced wear resistance and color stability, increased toughness, suitable for automotive basecoats, improved orientation of flake metal pigments |

EASTMAN |

| iSuoChem CAB-381-20 |

Good solubility, high viscosity, suitable for high viscosity coatings, enhanced wear resistance and color stability, large rheology modification, enhanced wear resistance and color stability |

EASTMAN |

| iSuoChem CAB-551-0.01 |

Excellent compatibility, low viscosity, suitable for UV curing coatings, improving hardness and construction performance |

EASTMAN |

| iSuoChem CAB-551-0.2 |

Excellent compatibility, low viscosity, suitable for high solid coatings, improving construction performance |

EASTMAN |

| iSuoChem CAB-531-1 |

Higher butyryl content, improved compatibility, suitable for high butyryl content coatings, improved compatibility and pigment wetting |

EASTMAN |

6. Does my project really need Cellulose Acetate Butyrate CAB resin? What are its advantages?

iSuoChem CAB Resin series is favored by the market for replacing Eastman CAB full series products. iSuoChem not only has the same product advantages as Eastman, such as pigment control, adhesion, toughness and construction performance, but is also suitable for industrial applications with high performance requirements.

With outstanding performance in solution transparency and price, iSuoChem CAB full series is more suitable for projects that need to control production costs and have high transparency requirements.

7. How to choose the right cellulose acetate butyrate product

1. Choose according to application requirements: Different applications have different performance requirements for Cellulose Acetate Butyrate. For example, automotive coatings require high weather resistance and wear resistance, while printing inks require good leveling and adhesion314.

2. Consider performance parameters: When selecting Cellulose Acetate Butyrate products, pay attention to parameters such as acetyl and butyryl content, molecular weight, solubility, etc. For example, Eastman CAB-381-2 has high viscosity and excellent flexibility, which is suitable for metal coatings and plastic coatings. iSuoChem CAB 381-2 can provide equivalent performance.

3. Suppliers and prices: There are multiple suppliers on the market that provide CAB products, with different prices and specifications. For example, the packaging specification of Eastman CAB-381-0.5 is 20KG/bag, which is suitable for occasions with low construction viscosity. iSuoChem CAB 381-0.5 can provide equivalent packaging.

8. FAQ

Here are some frequently asked questions about WPC decking:

Q: What is cellulose acetate butyrate used for?

A: Eastman cellulose acetate butyrate is mixed cellulose esters containing acetate and butyrate functional groups. They are commonly used as binders and additives in coating applications for a variety of substrates, including plastics, textiles, metal, and wood.

Q: Is cellulose acetate butyrate safe?

A: Yes. Cellulose acetate butyrate is a biodegradable and environmentally friendly material. Therefore, it must be environmentally friendly and safe.

Q: Do you provide technical guidance?

A: Yes. We have professional pre-sales, after-sales and technical engineers who can provide technical guidance on applications.

Q: Do you have price advantages?

A: Compared with Eastman, our cab cellulose acetate butyrate price has a great advantage.

Q: What are the main brands in the market?

A: Currently, the main international brand in the market is Eastman. iSuoChem can produce and sell all of Eastman's existing CAB products.

Q: What are the appearance of cellulose acetate butyrate?

A: We have white coarse cellulose acetate butyrate granule and fine powder.

Q: Why should we choose you instead of Eastman?

We have professional sales staff who can help you with pre-sales consultation, sample confirmation(Advanced sample managerment), follow-up of bulk production, export by sea and land, and customs declaration/clearance. Our price is very competitive. After it is dissolved, you can see that our transparency of cellulose acetate butyrate solubility is very high compared to Eastman. Please ask for a comparison test video from us.

9. Conclusion

Cellulose acetate butyrate has shown broad application prospects in the fields of coatings, printing inks, nail care and varnishes. Its excellent physical properties, chemical stability and environmental friendliness make it an important material in modern industry. By understanding the characteristics and application scenarios of CAB, users can choose suitable products according to specific needs and give full play to its performance advantages.