In the ever-changing construction industry, advances in materials science are crucial for promoting project quality, efficiency, and sustainability. From majestic skyscrapers to cozy homes, every structure relies on advanced building materials. Behind these materials lie hidden "unsung heroes" who play crucial roles at the microscopic level, ultimately determining a building's performance and longevity. Vinyl acetate-ethylene copolymer emulsion is one such indispensable and innovative material, its unique properties profoundly influencing the development of modern building materials.

1. What is VAE Emulsion?

VAE emulsion is a polymer dispersion composed of a copolymer of vinyl acetate and ethylene. By varying the ratio of these two monomers, the emulsion's properties can be precisely tailored to meet diverse application requirements.

In the construction industry, VAE emulsion is typically converted into a Re-Dispersible Emulsion (RDP Emulsion). This powder remains stable when dry, making it easy to store and transport. When added to water-based systems (such as cement-based mortars and gypsum-based putties), the VAE powder particles quickly absorb water and disperse, reforming into an emulsion. These redispersed emulsion droplets fuse during water evaporation, forming a continuous, elastic polymer film that firmly binds the inorganic particles (such as cement, gypsum, and fillers) in mortar or putty, providing additional performance enhancements.

| Property | Contribution to Performance |

| Flexibility | Prevents cracking and improves longevity in dynamic applications |

| Adhesion | Forms strong bonds with inorganic materials, enhancing durability |

| Water Resistance | Ensures materials maintain integrity in moisture-prone areas |

| Durability | Enhances overall mechanical properties of construction materials |

2. VAE emulsions give building materials "superpowers"

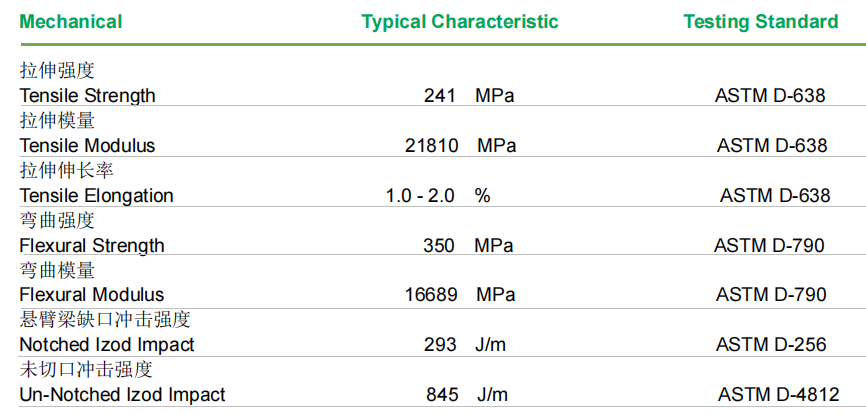

VAE emulsions (such as Vinnapas 400H) play such a crucial role in building materials due to their unique combination of excellent properties, which are highly compatible with cement-based materials:

2.1 Superior Adhesion

This is one of VAE emulsions' most important contributions. While cement-based materials possess a certain degree of adhesion, they often struggle to adhere firmly to smooth, dense, or porous substrates. VAE emulsions can:

- Form a strong bond: During the drying process, the polymer chains of VAE emulsions penetrate the microscopic pores of the substrate and form a continuous, highly adhesive polymer film on the surface of the cement particles.

- Improved Bonding to Various Substrates: VAE-based materials bond well to a variety of building substrates, including concrete, mortar, gypsum board, wood, metal, and insulation boards, greatly expanding their application range.

- Improved Interfacial Strength: The introduction of VAE significantly enhances the bond strength at the material interface, making the connection between the mortar layer and the substrate, between different mortar layers, or between the mortar and finishing materials such as tiles more secure and reliable.

2.2 Enhanced Flexibility & Crack Resistance

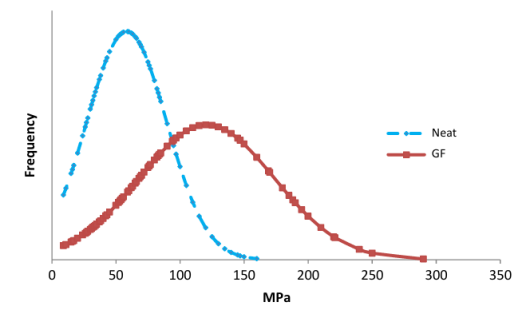

An inherent disadvantage of cement-based materials is their brittleness, which makes them prone to cracking when subjected to stress (such as temperature fluctuations, structural settlement, and vibration). VAE emulsions effectively address this issue:

- Introducing Flexibility: The incorporation of ethylene units into VAE copolymers imparts excellent flexibility to the polymer chains, resulting in a certain degree of ductility after drying and forming a film.

- Absorbing Stress: When the substrate undergoes slight deformation or temperature fluctuations that cause expansion and contraction, the flexible film formed by VAE absorbs and distributes these stresses, preventing the formation and propagation of cracks.

- Improved Impact Resistance: The presence of VAE also makes the material less susceptible to shattering upon impact, significantly enhancing its overall toughness.

2.3 Improved Water Resistance & Durability

The continuous polymer film formed by VAE emulsions significantly improves the material's water resistance and overall durability:

- Waterproof Barrier: VAE films act as an effective waterproof barrier, reducing water penetration, protecting structures from moisture erosion, freeze-thaw cycles, and preventing rusting of internal steel reinforcement.

- Chemical Resistance: VAE polymers generally exhibit good resistance to a wide range of chemicals, enabling the material to maintain stable performance in a wider range of environments.

- Extended Service Life: By enhancing adhesion, crack resistance, and water resistance, VAE significantly extends the service life of building materials and reduces ongoing maintenance costs.

2.4 Excellent Film Formation & Cohesion

The ability of VAE emulsions to form a continuous, uniform polymer film during the drying process is the foundation for the aforementioned properties:

- Particle Fusion: As water evaporates, the polymer particles in the VAE emulsion fuse from their dispersed state through forces such as van der Waals forces and hydrogen bonding, forming a dense, non-porous, continuous film. Improved.

- Cohesive Strength: The VAE film not only bonds to the external substrate but also acts as an internal "adhesive," holding together inorganic particles like cement and sand. This significantly enhances the cohesive strength of mortar or putty, preventing it from flaking or disintegrating.

2.5 Compatibility with Cementitious Systems

VAE emulsions (especially RDP forms) are specifically designed to work synergistically with inorganic binders such as cement and gypsum.

- Excellent Dispersibility: VAE powder quickly and evenly redisperses in water, forming a stable emulsion.

- No Impact on Setting Time: Generally, the addition of VAE does not significantly shorten or prolong the setting time of cement, making construction operations more convenient.

- Synergy: The flexibility, adhesion, and water resistance provided by VAE complement the high strength and hardness of cement-based materials, creating a high-performance composite material.

2. 6 Environmental Benefits

As people become increasingly concerned about health and the environment, the environmental advantages of VAE emulsions are becoming increasingly prominent:

- Low VOC emissions: VAE emulsions and products made from them typically have very low volatile organic compound (VOC) content. This not only helps improve indoor air quality and reduce harm to the human body, but also complies with increasingly stringent environmental regulations.

- Reduced material loss: VAE's improved material performance and durability mean less material loss and a longer lifespan, reducing resource consumption at the source.

3. Typical Applications of VAE Emulsions

Due to these superior properties, VAE emulsions (and their RDP forms) are widely used in:

- Tile Adhesives: Their excellent bond strength ensures tiles remain in place; their excellent flexibility adapts to the thermal expansion and contraction of the substrate and tiles, preventing hollowing and cracking.

- Self-Leveling Compounds: They significantly improve the adhesion, flexibility, and crack resistance of mortars, ensuring a smooth and durable floor screed. Wall Putties/Skim Coats: Improve the adhesion and crack resistance of putty, making it easier to sand and creating a smooth, even wall surface.

- EIFS: Used to bond insulation boards and facing mortar, providing excellent bond strength, impact resistance, and weather resistance.

- Repair Mortars: Strengthen the bond between the repair material and the existing structure, improving the durability and crack resistance of the repair layer.

- Waterproofing Materials: Used in flexible waterproof coatings or mortars, providing excellent waterproofing performance and crack resistance.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com